Fiber optic patch cords play a critical role in establishing reliable and high-speed connections in modern telecommunications and data networking infrastructure. These essential components provide the physical link between active network devices, such as switches, routers, and servers, enabling the seamless transmission of data over optical fiber cables. To ensure optimal performance and longevity of fiber optic networks, it is essential to adhere to a set of guidelines for selecting, installing, and maintaining fiber optic patch cords.

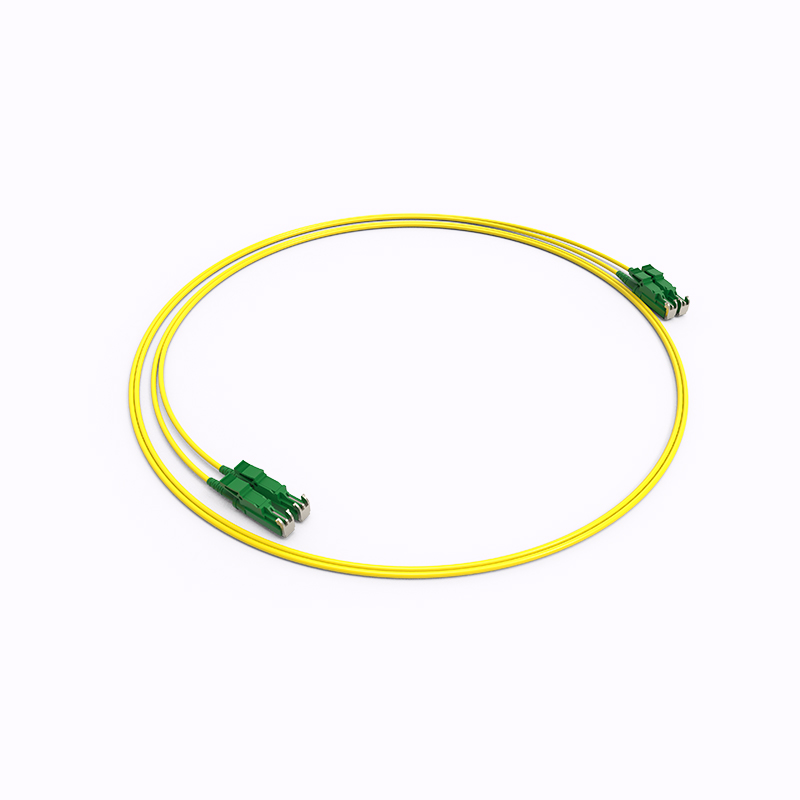

Choosing the Correct Connector Type: When selecting a fiber optic patch cord, it is crucial to consider the connector type compatible with the network equipment. Common connector types include LC, SC, ST, and MTP/MPO, each with its unique characteristics and applications. Careful selection ensures proper compatibility and reliable connectivity.

Matching Fiber Type: Fiber optic patch cords are available in single-mode and multimode variants, with different core diameters and transmission characteristics. Selecting the appropriate fiber type based on the network requirements, such as distance and bandwidth, is essential for optimal performance.

Quality and Reliability: Opting for high-quality patch cords from reputable manufacturers ensures reliability and longevity. Look for products that comply with industry standards and undergo rigorous testing to meet performance specifications.

Proper Handling and Storage: Handle fiber optic patch cords with care to prevent damage to connectors and fibers. Avoid bending beyond the minimum bend radius and protect connectors with dust caps when not in use. Store patch cords in a clean and dry environment to prevent contamination and degradation.

Precision Termination: Ensure accurate termination of patch cords to maintain low insertion loss and high return loss. Follow manufacturer guidelines and use appropriate termination tools and techniques, such as fusion splicing or mechanical connectors, to achieve optimal results.

Strain Relief and Cable Management: Use strain relief techniques, such as cable ties or bend-limiting boots, to minimize stress on fiber optic cables and connectors. Implement proper cable management practices to organize and secure patch cords, reducing the risk of accidental damage or disconnection.

Performance Testing: Conduct thorough testing of fiber optic patch cords using optical power meters, light sources, and OTDR (Optical Time-Domain Reflectometer) to verify performance parameters such as insertion loss, return loss, and continuity. Regular testing ensures compliance with specifications and identifies potential issues early.

Visual Inspection: Perform visual inspections of patch cord connectors and cables to check for signs of damage, contamination, or misalignment. Clean connectors with lint-free wipes and isopropyl alcohol to remove dirt and debris, maintaining optimal optical performance.

Regular Maintenance: Implement a routine maintenance schedule to inspect and clean fiber optic patch cords, connectors, and cable pathways. Replace damaged or worn-out components promptly to prevent signal degradation and network downtime.

Troubleshooting Procedures: Develop procedures for troubleshooting common issues with fiber optic patch cords, such as signal loss, intermittent connectivity, or excessive attenuation. Use diagnostic tools and techniques to identify and resolve problems efficiently, minimizing network disruptions.

Adhering to a comprehensive guideline for fiber optic patch cords is essential for ensuring reliable connectivity and optimal performance in fiber optic networks. By selecting the right patch cords, following proper installation practices, conducting thorough testing, and implementing routine maintenance procedures, network operators can maximize uptime, minimize downtime, and enhance overall network reliability and efficiency.